By Greg Clifton, Defense Opinion Writer.

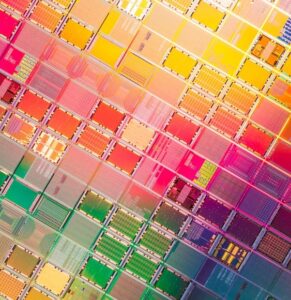

The U.S. CHIPS and Science Act has reignited domestic manufacturing and inspired a nationwide push to rebuild the local microelectronics ecosystem, which is imperative to maintaining the U.S.’s innovation superiority. But even as the momentum to build home-grown semiconductors grows, one crucial question remains: how do we ensure that domestic chip manufacturing strengthens national defense?

The drive toward semiconductor sovereignty stems from the COVID-19 supply chain crisis, which revealed just how fragile the U.S. access to critical technologies had become, as well as threats from other countries. For example, China’s increasing pressure on Taiwan, which is home to the majority of the world’s advanced chip manufacturing, has heightened concerns that Beijing could gain greater leverage over the global technology supply chain.

In response, the U.S. government and its technology partners have rightfully taken an all-encompassing approach to rebuilding the domestic semiconductor base.

U.S.-based companies are already investing in domestic fabrication capacity alongside government programs focused on workforce development and policies intended to support long-term semiconductor innovation.

These initiatives bode well for America’s defense posture because they help strengthen the country’s technological independence and mission readiness. A secure domestic chip ecosystem ensures that all agencies have trusted access to computing power without having to rely on an international supply chain. It gives defense agencies resources for actionable intelligence and real-time decision-making.

It also sets the stage for future-proofing mission capabilities by ensuring that platforms are suitable for multi-domain operations, advancing computing at the tactical edge and deriving performance gains from existing systems.

Readiness across domains

Successful defense across land, sea, air, space and cyberspace depends on technology that can perform reliably across multiple domains and with limited connection. Interoperability ensures systems connect easily and share data securely while reducing reliance on outdated, siloed technologies.

This approach delivers two key advantages. First, it brings modern, proven technologies into defense systems more quickly, as commercial providers are delivering interoperability through shortened development cycles. Second, adopting flexible and scalable chip architectures extends the life of critical systems by allowing agencies to upgrade capabilities as necessary.

Semiconductors are at the center of this interoperability. Chips form the connective tissue that allow disparate systems to interact with each other. By building semiconductors domestically, the U.S. gains greater control over developing secure and adaptable technologies that are designed for multi-domain operations.

Powering decisions at the tactical edge

The military often operates in environments with limited or no connectivity. This reality requires silicon that is optimized for the tactical edge and this lack of connection. Chips must not only be intelligent, but also small, rugged and efficient.

Modern architectures now allow for powerful, energy-efficient computing at the edge, enabling real-time decision-making without driving up costs. These edge-ready systems balance size, weight, power and cost while providing advanced analytics and AI capabilities.

Domestic chip manufacturers are making all this possible. Processing power that was once only found in central data centers is now contained in compact, portable forms, from ruggedized laptops to modular hockey puck-sized wafers embedded in edge systems, which process data closer to where it is generated to improve speed and reliability. These technologies combine CPUs, GPUs and neural processing units on a single piece of silicon, enabling powerful AI models to run locally, even in difficult environments.

Artificial intelligence can provide an assist

AI can also transform how defense organizations optimize their existing hardware, making it faster, more efficient and adaptable. Modern chipsets allow multiple compute engines to collaborate intelligently, assigning each workload to the most efficient processor for a given task. Instead of overloading one component, AI dynamically distributes processing to maximize performance, reduce bottlenecks, and extend system life.

However, the military services should look beyond just gaining efficiencies through existing hardware and seek to maximize the intelligence that so-called “classic AI” can provide. While generative AI, a class of models that can create new and contextually relevant outputs, is both the present and future of military intelligence, organizations should not overlook proven capabilities like machine learning, which learns and adapts from data and predictive analytics, which forecasts likely outcomes to support decision-making.

These technologies remain instrumental in providing actionable intelligence around everything from battlefield simulations to equipment maintenance. The Department of Defense should continue to invest in them accordingly – because they and domestic chipset manufacturing will provide the United States with an important tactical advantage in its ongoing effort to achieve technological dominance.

But America’s semiconductor renaissance is about more than manufacturing; it’s about ensuring our nation’s technological and defense superiority for decades to come. Defense leaders can accomplish this by validating platforms across domains, empowering the tactical edge and using AI to maximize the value of existing systems.

Greg Clifton is general manager for Intel Corp.’s government group.

Are you a Defense Daily reader with a thought-provoking opinion on a defense issue? We want to hear from you.

- We welcome submissions of opinion articles on national security, defense spending, weapons systems and related areas.

- We welcome submissions from lawmakers, administration officials, industry representatives, military officials, academics, think tank experts, congressional candidates, international experts and others on issues important to the national defense community.

- We welcome a diverse range of opinions all along the political spectrum.

- Email: editor@DefenseOpinion.com