Defense Daily

-

Tuesday, October 28, 2025

- Repurposing Of Reconciliation Funds For DoD Not A Solution, PSC Says

- As Army Plans JLTV Cut, AM General ‘On Track’ To Meet 2026 Fielding For Vehicles On-Order

- HII And South Korea’s Hyundai Agree To Jointly Bid For Navy Auxiliary Ships

- House Dems “Urgently Demand” End To Furloughs As Labs Send Workers Home

- Voyager Acquires Spacecraft Electric Propulsion Supplier ExoTerra

- After Union Narrowly Rejects Contract Offer, Boeing Says Focused On Contingency Plan

- Former Army Secretary To Become NTI President

-

Army

ArmyAs Army Plans JLTV Cut, AM General ‘On Track’ To Meet 2026 Fielding For Vehicles On-Order

As the Army plans to curtail future Joint Light Tactical Vehicle (JLTV) procurement, AM General has confirmed it remains on track to meet an initial fielding goal for the second […]

-

Navy/USMC

Navy/USMCHII And South Korea’s Hyundai Agree To Jointly Bid For Navy Auxiliary Ships

HII [HII] and South Korea’s HD Hyundai Heavy Industries (HHI) over the weekend signed a memorandum of agreement (MoA) to start “deeper collaboration” between the firms, including jointly bidding on […]

Tagged in: -

Congress

CongressRepurposing Of Reconciliation Funds For DoD Not A Solution, PSC Says

Using fiscal 2025 reconciliation law dollars to plug Defense Department fiscal holes from the government funding hiatus is untenable, warns the Professional Services Council (PSC), a group of 400 federal […]

-

Business/Financial

Business/FinancialAfter Union Narrowly Rejects Contract Offer, Boeing Says Focused On Contingency Plan

Boeing [BA] on Sunday said its defense business is focusing on the “next phase of our contingency plan” after union members voted against the company’s latest contract offer. Exactly what […]

-

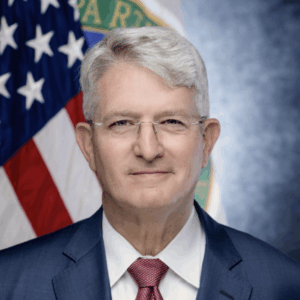

Nuclear Modernization

Nuclear ModernizationFormer Army Secretary To Become NTI President

Christine Wormuth, most recently the secretary of the Army, will be the Washington-based nonprofit Nuclear Threat Initiative’s (NTI) newest president and third CEO effective Nov. 17, the organization announced last […]

-

Space

SpaceVoyager Acquires Spacecraft Electric Propulsion Supplier ExoTerra

Voyager Technologies [VOYG] on Monday said it has acquired ExoTerra Resource in a deal that gives it capabilities in compact electric propulsion systems used to maneuver satellites in orbit. Terms […]

-

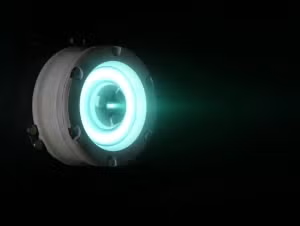

Nuclear Modernization

Nuclear ModernizationHouse Dems “Urgently Demand” End To Furloughs As Labs Send Workers Home

House lawmakers last week condemned the furloughs of 1,400 of Energy Department’s semi-autonomous National Nuclear Security Administration (NNSA) workers in a letter to Secretary of Energy Chris Wright and NNSA […]

-

Monday, October 27, 2025

- Defense Watch: Boeing Machinists, Big GD Award, New USV

- Northrop To Begin Full-Rate Production Of IBCS Soon, Looks To Develop Adaptive Version

- Hypersonic Missile Developer Castelion Nabs Army, Navy Awards For Platform Testing

- Avio Plans More Than $400 Million Spend, Much of It on U.S. SRM Production

- GD Posts Strong Third Quarter Results On Aerospace, Shipbuilding

- Space Systems Command Wants Comments Soon On RG-XX “Andromeda” Draft Solicitation

-

Monday, October 27, 2025

- Defense Watch: Boeing Machinists, Big GD Award, New USV

- Northrop To Begin Full-Rate Production Of IBCS Soon, Looks To Develop Adaptive Version

- Hypersonic Missile Developer Castelion Nabs Army, Navy Awards For Platform Testing

- Avio Plans More Than $400 Million Spend, Much of It on U.S. SRM Production

- GD Posts Strong Third Quarter Results On Aerospace, Shipbuilding

- Space Systems Command Wants Comments Soon On RG-XX “Andromeda” Draft Solicitation