Fincantieri Marinette Marine is starting construction on the first Constellation

-class frigate, the future USS Constellation (FFG-62), on Wednesday at its Marinette, Wis., shipyard after getting the go-ahead from the Navy following two reviews.

In 2020, the Navy awarded the company an initial $795 million contract for design, construction and delivery of the first new frigate in (Defense Daily, April 30, 2020).

Rear Adm. Casey Moton, Program Executive Officer for Unmanned and Small Combatants (PEO USC), told reporters on Monday that since the award Fincantieri and the production team completed the detail design of ship systems, placed materials suppliers under contract, developed a three-dimensional model used to support production, and significant shipyard capital improvements.

The Navy completed the critical design review in May and a production readiness review in July. Thereafter, the service granted approval to begin production. The Constellation is now scheduled to be delivered to the Navy in 2026.

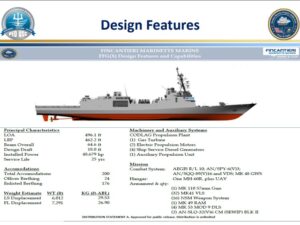

The Constellation-class is based on an Italian FREMM frigate parent design, also built by Fincantieri. The Navy required competitors to work off of parent designs to reduce program risk.

When asked why it took about 2.5 years to get from contract award to start of construction, Moton said there is a “fairly lengthy process of going through the functional design where you’re looking at system by system. And it’s a little bit of a spiral, if you change something that they have impact on others, so it just takes a while to move through that process.”

“In order to complete the design, the shipbuilder has to get all of their major vendors on contract. Because, we’re literally at the level where it’s not just – okay, here’s a pump. We need to know which pump because we’ve got to have the right circuit breakers to feed that pump,. So it is a quite detailed level, That takes time.”

Moton added that the Navy and Fincantieri mutually agreed reaching a high level of design maturity was the single biggest factor they could achieve to reduce risk in production.

“So we held ourselves to a high standard. And, at the end, there were even a couple of spots where we decided to continue maturing the design in order to meet that high standard, and it was the right thing to do and I think it’s going to pay dividends in construction,” he said.

Moton also clarified that while Fincantieri is the lead contractor for functional design, as in defining what the ship systems look like, Gibbs & Cox was the lead for the ship’s 3D model.

He noted the detail design is “just over 80 percent complete,” which was the Navy’s goal before starting fabrication.

“That’s a percentage beyond just a number. That percentage reflects two things: one is that we wanted to ensure that functional design was largely complete. And that’s important because that’s what sets the systems and the equipment selection and all those types of things.”

“And the other part of it is making sure that 3D model was complete enough to know that there’s still work that will happen at kind of the module level, compartment level, but making sure that those ship-wide things were mature and stable. So we are 80%, which is our goal, and I think that gives us a great foundation for moving into production,” Moton continued.

He also differentiated functional design to detail design by using the example of a fire pump.

“So functional design is, now I know everything on the ship that needs the fire main, either for cooling or for firefighting. So now I’m picking out how big the pump needs to be, I’m figuring out the size of the pipe, I’m figuring out where the pipe needs to run through the ship to get to its equipment. The detailed design, or really the 3D model…is now I’m in a specific space, and the fire main has to run to a specific piece of equipment. And where is that pipe, and how is it attached to the bulkhead, and all the way down to what brackets does it need so that the shipbuilder can go buy them.”

The Navy’s fiscal year 2023 budget request said the Navy plans to alternate between buying one and two frigates per year over the next five years, starting with just FFG-62 in 2023. Previously, under the Trump administration, the Defense Department considered options to eventually move to using two shipyards to procure more than the originally planned 20 total frigates and at a faster rate than one shipyard allows.

The Navy contract with Fincantieri inherently allows this by including a Technical Data Package (TDP) option. A TDP includes all the technical and manufacturing information needed to build and support a given program. The service can exercise the option for Fincantieri to produce a TDP any time before the initial 10-ship frigate contract ends.

Moton said it will take Fincantieri about a year to produce the TDP once the Navy orders it, but he noted there are incentives for the Navy to wait until the program is further along.

“There is a lot of advantage in terms of holding on getting that package because as the shipbuilder moves through production, there will be fixes and changes and things that need to happen…it’s kind of to our advantage to sort of wait as long as we can to get those good fixes, but also support when it looks like we’re going to need to put [out a request for proposals] if and when we do that for a second builder.”

Moton said there is no set timeline for when the Navy decides to add a second shipyard.

“We’re just going to see what happens in the [Program Objective Memorandum], inform those discussions. The biggest thing that we have to do on the programmatic end, is to procure the TDP.”

In April, Constellation-class frigate Program Manager Capt. Kevin Smith said the current pace of frigate construction allows them to better wring out any issues in construction and decisions on a second shipyard may come after Fincatnieri starts completing ships. He also said he expected the Navy to order the TDP from Fincantieri during the first 10-ship contract period (Defense Daily, April 7).

Another senior Navy official also told reporters the service first focused on getting this first vessel working through the construction process and getting the shipyard working at a good rate before moving to second yard decisions.

“I think step one is getting the first ship up and going and working through that construction process. And I think, as we go forward getting that first yard on a good cadence. I think, as we go forward we want to then look at how do we make sure that we have the ability to meet our requirements. Right now, I think we’re in a good place to meet the requirements that we have in the coming years with the shipyard that is beginning work in Fincantieri,” Tommy Ross, Performing the Duties of Assistant Secretary of the Navy for Research, Development and Acquisition (PTDO ASN RDA), said.

However, he noted the potential second yard is something the Navy wants to take a “close look at.”

“And then how do we make sure that we have a robust industrial base that can meet our needs, compete to deliver the best possible performance, etc? So I think the short answer is it’s going to be an evolving process but it’s definitely something that we want to continue to look at as we get more information about our future plans, requirements and industrial base ability to meet our needs,” Ross added.

Moton said the only supply chain issues he is looking at in frigate construction are the same ones affecting shipbuilding nationally.

“A particular one for us that has been an issue, actually in other programs, has been microelectronics. It should be no surprise to anybody because it’s a national level issue that I think eventually drove things like the CHIPS Act. So we are certainly going to have to watch all of that and how it’s going to impact production. There’s nothing that I would report today that’s come to fruition. But certainly, I would say it’s almost something that we’re having to do in all of our programs.”

Moton also said skilled industrial labor is another production and supply chain issue.

“I’m not telling you anything that I think you haven’t heard from at a national level, or from my counterparts in the submarine construction world, or any of those areas. Frigate is certainly going to deal with the same challenges that we’re facing as a nation. We’ll have specifics to work through,” he said.

However, Moton said he believes the shipbuilders have a good plan “and they understand what they need, including in terms of resourcing and they have a good plan to go after it.”