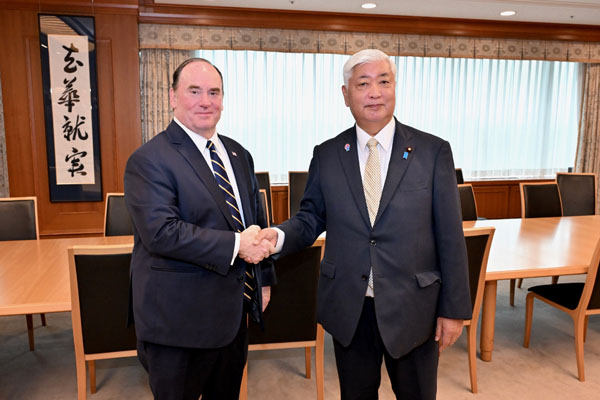

In his first visit abroad as Secretary of the Navy, John Phelan pitched to the Japanese government that the two countries work to cooperate on dual-use shipbuilding and also continue promoting efforts for industry to invest in domestic U.S. shipbuilding capabilities.

Phelan on Monday said he met with top Japanese officials during his first international trip as secretary.

“During our discussions I reinforced our close naval partnership, and a shared commitment to a stronger allied maritime industrial base,” he said in a Twitter/X

post.

The Navy’s official readout said he sought to reinforce the department’s commitments to the alliance with Japan and discussed opportunities to improve security cooperation, enhance modernization, and increase investments to challenge China’s provocations.

While there, Phelan toured Japan’s second largest shipbuilder, Japan Marine United (JMU), “to understand industry best practices and encourage investment in American shipyards, reinforcing President Trump’s America First agenda,” the readout said.

In an exclusive interview with Nikkei Asia ahead of meeting with Japanese government officials, Phelan said the countries should look at all options for using dual-use shipbuilding to build commercial ships with military applications.

He argued this is needed in response to how the Chinese shipbuilding industry and government design their commercial ships with a military application in mind that seems to be a quick conversion capability. This means commercial ships must be built to standards that likely allow it to transport military systems like tanks, with the government funding modifications to the original design.

“I don’t think we’re doing a similar sort of thing and I think it’s very important,” Phelan said.

Given the U.S. Navy and Japanese Maritime Self-Defense Force operate jointly, he argued they should “try to build that into both our commercial and our military shipbuilding.”

Phelan is also set to visit multiple shipyards in South Korea during his foreign trip and is spending time lobbying for more investment in American shipyards.

He told Nikkei Asia that after visiting East Coast shipyards he saw “there wasn’t a lot of room to add capacity” to those shipyards and that “given what we need to build and where we’re at … I would suspect the West Coast would probably be an area we will definitely consider.”

This effort to get more foreign investment continues a trend started by former Navy Secretary Carlos Del Toro with his own visits to the region and with allied country shipbuilders.

Del Toro’s visit was ultimately followed by South Korea’s Hanwha purchasing Philly Shipyard for $100 million last year, claiming they want to boost it back to a 1940s-level of national prominence (Defense Daily, Oct. 24, 2024).

More recently, this month HII [HII] and South Korea’s HD Hyundai Heavy Industries (HHI) signed a memorandum of understanding (MoU) to explore opportunities to work together on accelerating defense and commercial ship production projects (Defense Daily, April 7).

Concurrently, Fairbanks More Defense also signed an MoU with HD Hyundai to explore opportunities to collaborate on international Navy initiatives (Defense Daily, April 18).

This trip occurred just as the Republican leaders of the House and Senate Armed Services Committees published their recommendations for the current reconciliation bill, with $33.7 billion devoted to naval shipbuilding and industrial base funding through 2029.

Beyond major shipbuilding programs and unmanned systems, the bill recommendations include billions in manufacturing improvements over 15 workforce and industry initiatives, with relatively specific commitments related to advanced manufacturing, similar to what is done in Japanese and South Korean shipbuilding (Defense Daily, April 28).

This includes $750 million for additional supplier development across the naval shipbuilding industrial base, $500 million for additional dry-dock capability, $500 million for adoption of advanced manufacturing techniques in the maritime industrial base, $492 million in next-generation shipbuilding techniques, $450 million for additive manufacturing for wire production and machine capacity for shipbuilding industrial base, another $450 million in additional maritime industrial workforce development programs, $450 million for application of autonomy and artificial intelligence to naval shipbuilding and $400 million to expand collaborative campus for the shipbuilding industrial base.

Beyond these relatively large ticket items, the lawmakers recommend other specific investments including $250 million each for additional advanced manufacturing processes across the naval shipbuilding industrial base, expansion of accelerated Training in Defense Manufacturing program and domestic production of turbine generators for the shipbuilding industrial base.

The bill has smaller initiatives geared toward $110 million for a rolled steel and fabrication facility for the shipbuilding industrial base, $85 million for U.S.-made steel plates for shipbuilding, $50 million for machining capacity for naval propellers for shipbuilding and $50 million for expansion of cold-spray repair technologies.

The steel sections are notable because last month the Navy’s acting top acquisition official and currently performing the duties of Under Secretary of the Navy Brett Seidle admitted Trump administration steel and aluminum tariffs could increase shipbuilding costs (Defense Daily, March 27).

Seidle said in 2023 about half of the aluminum and one-third of the steel used in naval shipbuilding came from Canada. Sen. Tim Kaine (D-Va.) at the time argued it would be hard to quickly switch metal providers to avoid the impacts of the tariffs. In March, Trump imposed an effective 25 percent tariff increase in Canadian aluminum, steel and steel derivative products.