Norway on Thursday signed a contract with Lockheed Martin [LMT] to supply eight of its TPY-4 radars as the country’s future air surveillance capability, with options for three additional radars.

Lockheed Martin noted the deal makes Norway the first international customer for the new TPY-4 radar, which the company is currently providing for the U.S. Air Force’s Three-Dimensional Expeditionary Long-Range Radar (3DELRR) program to replace its legacy TPS-75 radar.

“We are grateful to be selected to help protect the safety of Norwegians. The TPY-4 is a continued advancement of our 21st century security vision supporting joint all domain operations for the United States and its allies,” Chandra Marshall, Lockheed Martin’s vice president of radar and sensor systems, said in a statement. “Norway joins the U.S. Air Force as our first NATO partners for the TPY-4 radar, and we look forward to offering this radar to solve evolving challenges of international partners.”

Norway’s Ministry of Defence said the first TPY-4 radar is expected to be in place by the end of 2025, with deliveries to be completed by 2030.

“The contract marks an important milestone for the Norwegian defense sector. Three of the new radars will be installed in existing locations, replacing current systems, while five will be installed in new locations. The new radars will enable the Norwegian Armed Forces to maintain its continuous surveillance of both Norwegian and surrounding air space, acting as NATO’s eyes in the north,” Norway’s Minister of Defence Bjørn Arild Gram said in a statement. “Airplanes, missiles, and drones have become an important part of modern warfare. It is therefore of the utmost importance to have systems that can monitor this domain. Not only for ourselves, but also for our allies in NATO. These new radars will improve the range of our view considerably.”

The U.S. Air Force announced in March that Lockheed Martin beat out Northrop Grumman [NOC] to provide the new 3DELRR radar, after both companies had received integration contracts under the preceding SpeedDealer program (Defense Daily, March 11).

Lockheed Martin officially received the first production order for two TPY-4 radars on March 29, with the 3DELRR program including options to potentially provide up to 35 of the new radars.

The company also noted it has leveraged “an extensive Norwegian supplier-base” for the TPY-4 program, to include Kongsberg building the system’s Platform Electronics SubSystem.

“Our strong relationship with Lockheed Martin exemplifies the importance of building durable and trusted partnerships to serve both national and international customers. Together we will deliver world-class products within radar technology to the Norwegian Armed Forces. This contract is not only important for us as a strategic partner for the Norwegian Armed Forces but also for our subcontractors in Norway,” Eirik Lie, president of Kongsberg, said in a statement.

Company officials told reporters during a media visit to the company’s facility near Syracuse in late April that the first TPY-4 radar was set to begin 15 months of open-air testing at its nearby site in Cazenovia, New York.

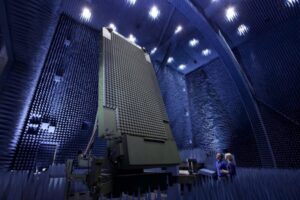

During the visit, reporters saw the first TPY-4 radar housed in an anechoic chamber at the company’s facility, where officials are able to gather data on the system’s performance in a controlled environment before the next phase of testing (Defense Daily, April 27).

Marshall told reporters at the time that the software-enabled nature of TPY-4 will allow for the Air Force to more seamlessly upgrade the radar as the mission set evolves.

“The threats are continuously changing, so that [software] capability allows [the customer] to not have to send back the system for us to upgrade the hardware for them to defend against new threats. You update the software, push it to the radar and you’re able to meet the missions that they have to meet. Sending the system back and changing the hardware is very costly and it’s something that we’re very mindful of when we design our systems,” Marshall said during the visit.