A new Government Accountability Office (GAO) report recommends the Navy increase the involvement of the Supervisors of Shipbuilding, Conversion and Repair (SUPSHIPs) to improve shipbuilding oversight and help the Navy make better informed decisions.

SUPSHIPs are the Navy Department’s on-site technical, contractual and business authority for construction of Navy vessels, with separate offices co-located with major shipbuilders. They operate under the direction of the Deputy Commander of Naval Sea Systems Command’s (NAVSEA) Logistics, Maintenance and Industrial Operations Directorate.

According to the GAO report, while prime contractors are responsible for controlling the quality of their work, “the Navy relies on the SUPSHIPs, as the government’s primary onsite representatives, to perform quality assurance oversight during ship construction at private shipyards.”

The SUPSHIPs are primarily responsible for providing quality assurance; surveillance of contractor business systems; contract administration and project management, logistics and financial administration for the shipbuilding contracts.

The report, Navy Shipbuilding: Increasing Supervisors of Shipbuilding Responsibility Could Help Improve Program Outcomes, was published on April 12.

GAO conducted this review because the FY 2021 defense authorization act directed it. To conduct the audit, GAO reviewed DoD and Navy regulations, policy, instructions, guidance and reporting. It also selected 12 ships delivered since 2017 for case study reviews of SUPSHIPs’ activities. The performance audit lasted from November 2020 to April 2022.

GAO noted this came after a 2018 report found lead ships in six Navy programs experienced delays ranging from six months to six years with cost growth upward of 154 percent. It also has found the Navy regularly accepts delivery of incomplete ships with “significant uncorrected deficiencies.”

“Over the past decade, we have identified concerns with the business cases for Navy shipbuilding programs that have led to persistent cost and schedule growth,” the report said.

GAO specifically pointed out specific problems in new vessels: persistent propulsion problems with the Freedom-variant Littoral Combat Ships, deficiencies with Advanced Weapons Elevators on the USS Gerald R. Ford (CVN-78) leading to delays over four years after the aircraft carrier was accepted, and quality issues with a special treatment not adhering to Virginia-class attack submarine hulls requiring costly unanticipated maintenance.

“Collectively, these results have raised questions about the Navy’s ability to effectively oversee shipbuilder performance throughout the construction of new ships,” GAO said.

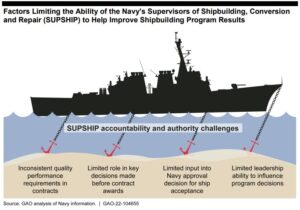

GAO said there are four main barriers preventing SUPSHIP from helping further improve shipbuilding contract effectiveness and accountability given this record.

First, GAO said SUPSHIP is limited in providing consistent shipbuilding oversight due to variation in quality requirements across shipbuilding contracts.

“As noted by SUPSHIP officials in our current and prior work, the regular omission of quality requirements included in the standard impedes their ability to have consistent quality assurance expectations for shipbuilder activities and for information across different ship classes and shipyards. This inconsistency reduces the Navy’s ability to effectively conduct oversight and can lead to insufficient quality assurance data,” the report said.

GAO said SUPSHIP Management officials told them “that they continue to see value in using a common contractual standard to create consistent quality requirements that support effective surveillance of shipbuilding quality. These officials added that, since the Navy did not use the quality standard over the past decade, a Navy evaluation of the existing standard’s requirements would help ensure the requirements remain relevant and account for changes in shipbuilding.”

SUPSHIPS also only provides limited input before contracts are awarded, keeping the Navy from leveraging their expertise to support “well-informed decision-making,” the report said.

While NAVSEA offices seek input from SUPSHIPs before contract awards, “officials from the SUPSHIPs and shipbuilding programs for our case studies said that, in practice, they generally provide limited, ad hoc input during the pre-award phase of the shipbuilding process,” GAO said.

“As a result, the Navy does not consistently leverage the SUPSHIPs’ unique subject matter expertise on how past decisions and performance across Navy shipbuilding programs have affected cost, schedule, and quality outcomes to inform early program decisions,” the report continued.

The report argued the omission of SUPSHIP reporting from the Navy’s process for approving acceptance of ships from the shipbuilders reduces accountability and misses the chance to make sure “independent SUPSHIP input on ship quality and readiness informs this key decision.”

The fourth issue is that SUPSHIPs’ position within NAVSEA and their accountability to different technical and acquisition organizations “dilutes their ability to be a distinct, authoritative voice in decision-making for Navy shipbuilding programs.”

GAO noted Congress passed legislation in December 2021 to establish a Deputy Commander dedicated to SUPSHIPs that may help improve their authority and accountability.

The report acknowledged improving SUPSHIPs’ involvement and accountability “will not on its own eradicate the long-standing problems that these programs have had with cost, schedule, and performance.”

“However, improvements to maximize the SUPSHIPs’ value in shipbuilding oversight and better harness their direct knowledge of shipbuilding activities can contribute to the Navy making better-informed decisions when setting and attempting to fulfill expectations,” the report continued.

GAO made five recommendations to the Secretary of the Navy. The first one is that the Secretary ought to determine if NAVSEA’s Quality Program Standard for Construction of Naval Vessels requires updates and then ensure regular use of the standard in shipbuilding contracts.

GAO also recommended the Navy evaluate whether opportunities exist for additional targeted oversight by the SUPSHIPs of critical government-furnished equipment away from the shipyards.

The report recommended the Navy guarantee that before NAVSEA makes contract award decisions, it evaluates the extent to which a shipbuilding contract to a prime contractor that is not the actual shipbuilder presents additional government risk related to business systems compliance and NAVSEA should determine options to mitigate the risk.

Notably, that scenario occurred with the Freedom-variant LCS, where Lockheed Martin [LMT] is the prime contractor but Fincantieri‘s Marinette Marine is the actual shipbuilder.

GAO also recommends the Navy Secretary ensure NAVSEA instructions are updated to provide the SUPSHIPs with direct representation in the evaluation and decision-making processes for all shipbuilding programs, starting with pre-contract award stages of requirements development and ship design.

The last recommendation is the Secretary require that SUPSHIP’s Deputy Commander provide a report to the Chief of Naval Operations that attests to the quality and readiness of each ship before approval of ship acceptance.

The report noted the Navy concurred with all five recommendations overall, but had comments on two of them. Ultimately, due to the comments, GAO amended its last recommendation allowing for the SUPSHIPs reports to run through NAVSEA, without circumventing the chain of command.